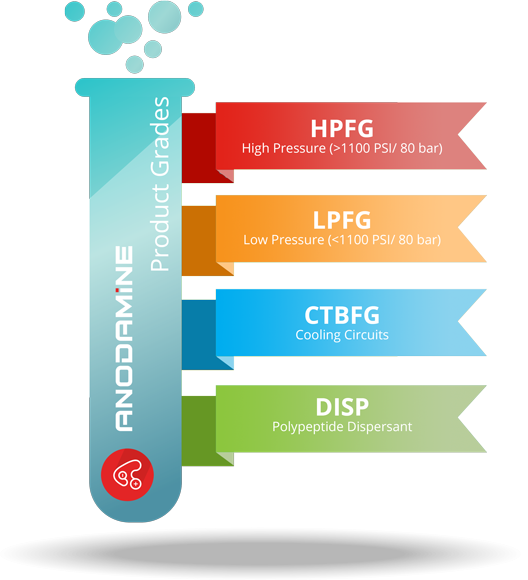

Products

Safety + Reliability + Availability

HPFG

High pressure treatment technology for passivation of ferrous and mixed metallurgy sub-critical drum units, natural & forced circulation, super critical once though units, HRSG’s with evaporative and ACC cooling.

LPFG

A treatment technology for all medium and low pressure users. Formulations contain dispersants and optional neutralizing and/or alkalizing amine blends. Neutralizing amines are not mandatory and ammonia can be substituted.

CTBFG

A treatment technology for cooling circuits with optional food grade combination dye that absorbs light at the wavelength required for photosynthesis of algae.

DISP

A non-eutrophication, environmentally compatible poly-peptide dispersant used in cooling circuits and all low/medium pressure boiler applications.

SDS information available by request: [email protected].

2-Pump Non-Containment

Our economy line offers an accurate dosing solution while maintaining a small footprint. Typically used for dosing Anodamine into one unit: one pump is operational whilst the other is on standby. Maintains full auto and manual functional control and quality craftsmanship as with our other dosing solutions.

- 1 boiler steam circuit

- 2 pumps (1 operational & 1 standby)

- No self-containment

2-Pump Self-Containment

An accurate dosing system, typically used for dosing Anodamine into one unit. Also contains a 304 SS 1/8” self-containment system and customizable protective bars to prevent any damages to pumps or dosing components. The bumpers location are customizable to allow for safe loading and interchange of IBC chemical containers.

- 1 boiler steam circuit

- 2 pumps (1 operational & 1 standby)

- SS Containment pond

- Protective bumpers

4-Pump Non-Containment

A compact alternative dosing system with a small footprint to allow for treatment of two operational steam generators from one chemical tote. One pump is operational whilst the other is on standby for each unit. Maintains full auto and manual functional control and quality craftsmanship as with our other dosing solutions.

- 2 boiler steam circuits

- 2 pumps (1 operational & 1 standby for each unit)

- No self-containment

2-Pump Self-Containment

An alternative dosing system with a self-containment system to allow for treatment of two operational steam generators from one chemical tote. Also contains a 304 SS 1/8” self-containment system and customizable protective bars to prevent any damages to pumps or dosing components. The bumpers location are customizable to allow for safe loading and interchange of IBC chemical containers.

- 1 unit

- 2 pumps (1 operational & 1 standby for each unit)

- SS Containment pond

- Protective bumpers

Ammonia System

A customizable dosing system that contains two dosing pumps with different displacement capabilities. One pump with high volume displacement (typically used for startups) and one pump with low displacement characteristiscs (used for maintenance dosage and optimal pH control).

- Optimal pH control during startups and normal operation

- 1 high volume displacement pump

- 1 smaller volume displacement pump