When Anodamine first visited the refinery we were shocked by the iron levels in the returning condensate.

Thanks for your recent audit from Anodamine, the audit revealed many areas for improvement that will be very beneficial in the long run.

After application of Anodamine to the feed water system, we measured a dramatic reduction of cycle corrosion products during unit starts and transient load operation.

Anodamine demonstrates good properties of pitting and crevice corrosion inhibition.

I can only attribute a 50% reduction in startup time to improved steam and condensate treatment. We have found remarkably less tube fouling when we cleaned the boilers for annual inspection. Thank you Anodamine!

The Anodamine treatment within about 7 days of starting, reduced the iron levels in our condensates dramatically.

Our system went from from poor performance and multiple tube failures per year, to a good system with no tube failures for multiple years. The leak clamps became a thing of the past with MOC documents used to monitor that progress.

Makeup water was reduced as the blowdown rates dropped as a result of the Anodamine, versus the conventional sulfite and amine additions.

Anodamine is an effective corrosion inhibitor of crevice corrosion of both mild steel and ferric stainless steels in sodium chloride solutions.

The use of Anodamine technology to protect out-of-service metal surfaces. Utility equipment wold be ready for immediate operation while also protected from corrosive conditions.

Cleaner unit start-ups during the trial suggest that both short-term and long term lay-up protection is optimized (without a nitrogen blanket, without deoxygenated makeup or maintaining a condenser vacuum).

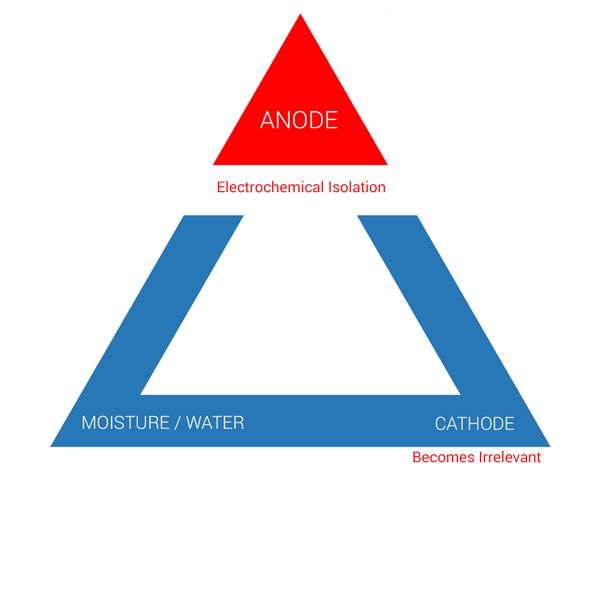

How It Works

Electrochemical Isolation

Through its selective nature, Anodamine specifically targets virgin metal surfaces to form a protective barrier.

In result, an electrochemical isolation of the anode occurs so that metal is protected and the corrosion process is terminated.

Anode Isolation

The anode (capital plant) is protected with a mono-molecular film that provides ultimate protection, without compromising heat transfer.

Cathode Irrelevant

Through isolation of the anode, a complete metal protection occurs irrespective of oxygen concentration.

Protection with Conventional Chemistry

For metal protection, conventional chemistries utilize the formation of an inorganic crystalline, hydrophilic corrosion product oxide (typically magnetite) formed on the virgin metal. This oxide’s protection characteristics and sustainability are directly affected by the operational physical and chemical variations, thus making complete metal protection an elusive goal.

Protection with Conventional FFAs

Conventional film-forming amines (FFAs) form a dangerous barrier on top of the epitactic oxide. What appears to be a super hydrophobic barrier is actually a trapping of inorganic contaminants between the film and the base metal. As a result, under deposit corrosion, pitting, hydrogen evolution, and embrittlement occur.

Protection with Anodamine

Anodamine has a molecular orientation and functionality/architecture which allows it to permeate through existing oxide layers (epitactic and topotactic) until it reaches the topotactic to base metal interface. The polarization and electron density that exists at this interface causes the selective attraction for Anodamine. State 1 and virgin metal protection occurs within 24 hours of dosage.

Get Started

|

1

|

Contact us by email or phone. |

|

2

|

An engineer will explain how Anodamine works. |

|

3

|

A chemist will provide a complimentary analytical survey of your sites’ steam and cooling cycle system and compare it with ASME and international standards. |

|

4

|

An engineer will provide you with a complete complimentary report, including the health of your steam and cooling system and expected savings in water and fuel costs which your site would experience utilizing Anodamine. |